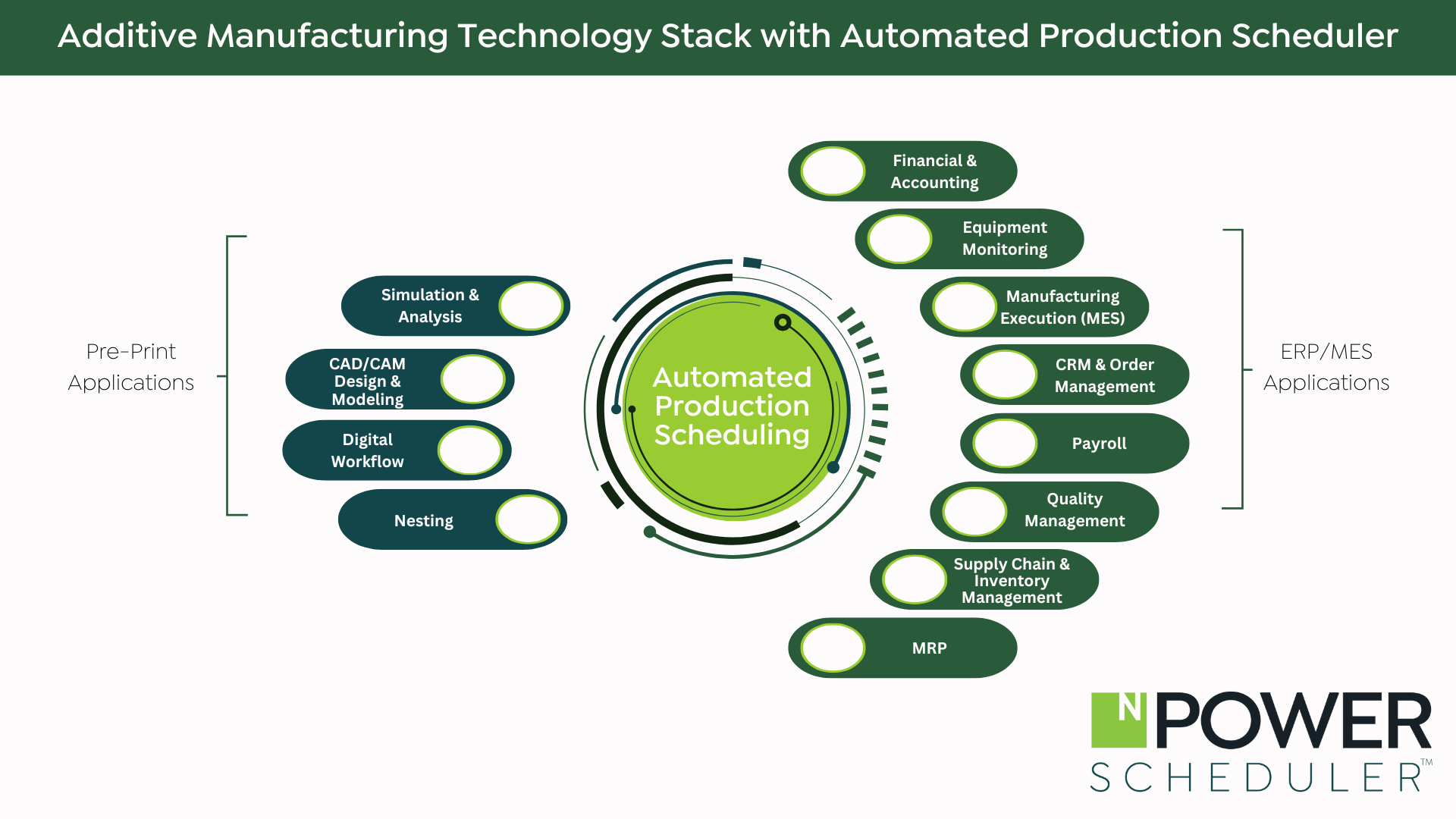

Where nPower Scheduler™ Fits in the Additive Manufacturing Technology Stack

In additive manufacturing (AM), efficiency is key—from design and build preparation to production scheduling and post-processing. The AM technology stack consists of various software solutions that streamline operations, enhance productivity, and ensure on-time delivery. While many businesses rely on CAD, nesting, ERP, and MES solutions, there’s one critical piece that often gets overlooked: Automated Production Scheduling.

That’s where nPower Scheduler™ comes in. It serves as the essential link between pre-print software and ERP/MES applications, creating an optimized production plan that maximizes throughput, improves machine utilization, and ensures on-time delivery. Without an automated scheduling solution like nPower Scheduler™, even the most advanced AM operations risk inefficiencies, delays, and resource underutilization.

Understanding the Additive Manufacturing Software Stack

Let’s break down where nPower Scheduler™ fits within the AM technology ecosystem.

- Pre-Print Software Applications

Before production begins, additive manufacturing requires a range of pre-print tools to design, simulate, and prepare builds.

- CAD/CAM Design & Modeling – Software like Autodesk Netfabb and Ansys Additive enables complex design creation and modeling for AM components.

- Nesting Software – Tools like Materialise Magics and Autodesk Fusion 360 optimize the layout of parts on the build plate, ensuring material efficiency and faster print times.

- Simulation & Analysis – Solutions such as Siemens NX AM help manufacturers simulate the AM process, identify potential issues, and improve build success rates.

- Digital Workflow & Monitoring – Platforms like Materialise Streamics and Authentise automate data preparation, track job progress, and provide real-time monitoring of AM production.

➡ However, none of these solutions schedule the full production process. While they optimize build preparation, they do not coordinate resources, manage shop floor operations, or ensure on-time delivery.

- ERP & MES Applications

Once a part is ready for production, enterprise software like ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems) handles inventory, production tracking, and quality control.

- CRM (Customer Relationship Management) – Systems like Salesforce and Microsoft Dynamics track customer orders and service interactions.

- Material Resource Planning (MRP) – Ensures raw materials are available for scheduled production.

- Manufacturing Execution Systems (MES) – Tools like Siemens Opcenter and Rockwell FactoryTalk provide real-time shop floor visibility, but they don’t optimize scheduling.

- Supply Chain & Inventory Management – Helps manage material flow, warehouse inventory, and procurement needs.

- Quality Management & Equipment Monitoring – Solutions like EOS Smart Monitoring ensure machines run at peak efficiency, while QMS software maintains high manufacturing standards.

➡ These tools track and monitor production, but they don’t dynamically adjust schedules to maximize machine utilization and meet customer deadlines.

- The Missing Piece: Automated Production Scheduling

Even with the best CAD, MES, and ERP solutions in place, manufacturers still face:

❌ Bottlenecks caused by inefficient resource allocation

❌ Underutilized additive machines due to poor scheduling

❌ Missed customer deadlines because of disconnected planning tools

❌ High labor costs from reactive scheduling instead of proactive optimization

That’s where nPower Scheduler™ completes the technology stack.

✅ Fully Automated Scheduling – Eliminates manual scheduling errors and inefficiencies.

✅ Optimized Resource Utilization – Dynamically assigns jobs to the right printers and post-processing equipment.

✅ Seamless ERP & MES Integration – Syncs with existing systems to provide a holistic production view.

✅ On-Time Delivery Guarantee – Ensures parts are scheduled to meet customer deadlines efficiently.

✅ ROI-Driven Performance – Delivers a recurring annual 300%+ ROI by increasing throughput and reducing wasted capacity.

See the ROI for Yourself

nPower Scheduler™ transforms additive manufacturing efficiency—but you don’t have to take our word for it.

📊 Use our free ROI Calculator to see how much time and money your business could save.

🔍 Get a free Scheduling Audit from our expert consultants to uncover hidden inefficiencies in your current workflow.

💡 Ready to optimize your AM production? Let’s schedule smarter. Contact us today at npowertech.com to get started! 🚀

#AdditiveManufacturing #nPowerScheduler #ProductionScheduling #ERPIntegration #ManufacturingEfficiency

What Is Automated Production Scheduling with nPower Scheduler™?

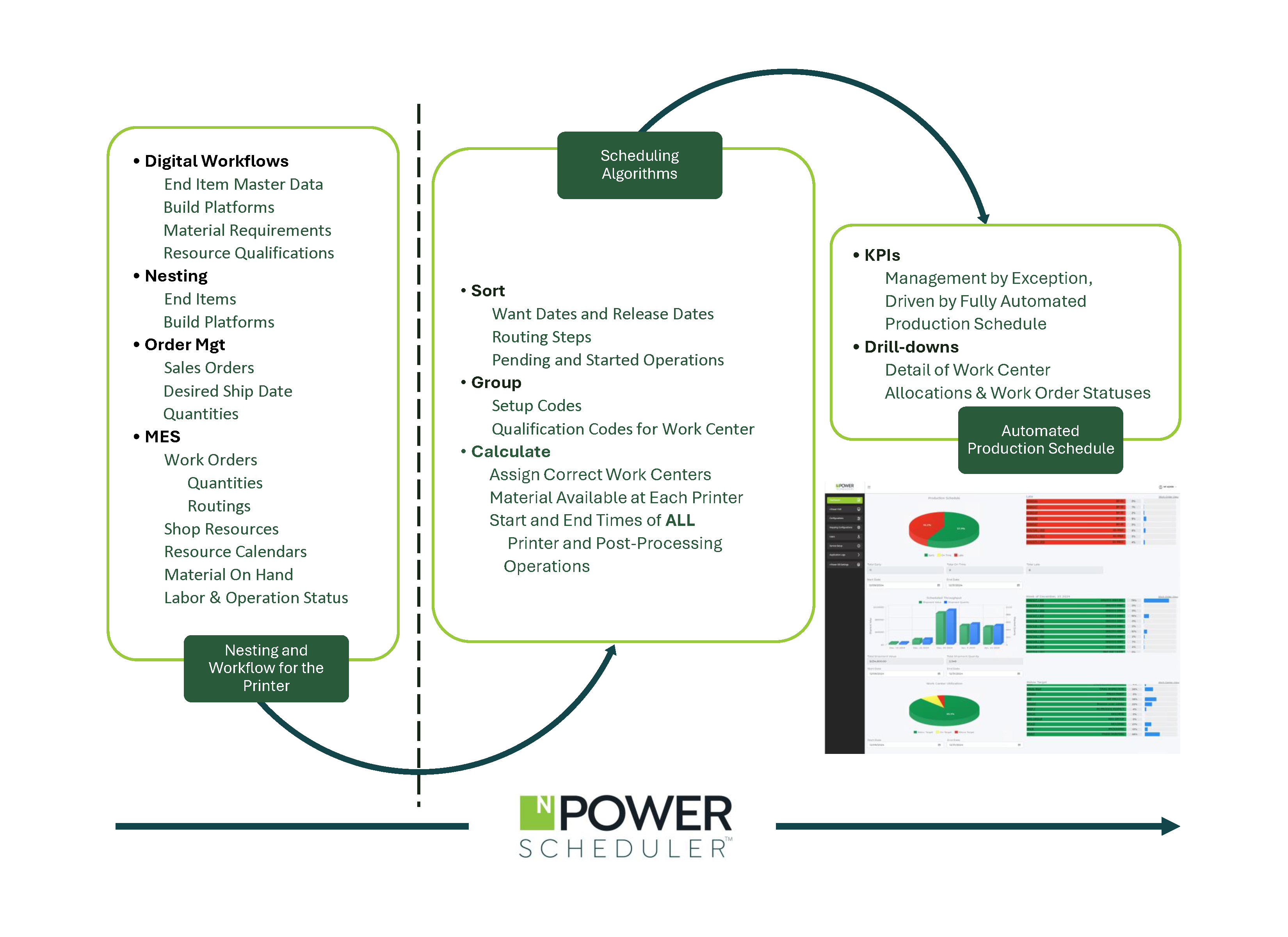

The nPower Scheduler™ is an automated, ERP-agnostic solution tailored to the complexities of additive manufacturing. Unlike manual methods or basic scheduling tools, nPower Scheduler™ provides a comprehensive, software-driven approach that optimizes every stage of production, ensuring precision, efficiency, and on-time delivery.

Key Features of the nPower Scheduler™:

- Automated Precision: Fully software-driven, nPower Scheduler™ eliminates human error, ensuring every task is scheduled accurately.

- Optimized Resource Utilization: Automatically assigns tasks to the right machines, balancing workloads while considering availability, technical requirements, and capacity.

- End-to-End Scheduling: Schedules the entire production process, from 3D printer build plates to post-processing operations like deburring, milling, and inspection—all with a single click.

- On-Time Delivery Assurance: Dynamically adapts to changes, ensuring every job meets customer “want dates” for consistent on-time delivery.

While nesting focuses on optimizing parts on the build plate, nPower Scheduler™ coordinates every step beyond the printer, providing a fully integrated solution for your entire shop floor.

Why Nesting and Scheduling Work Best Together

Additive manufacturing is a complex process involving multiple phases, resources, and deadlines. Nesting ensures the printer is used efficiently, but only scheduling software like nPower Scheduler™ can automate and optimize the full production lifecycle. Together, these tools:

- Maximize efficiency by automating both the printing and post-processing stages.

- Align production goals with business objectives, such as improved resource allocation and on-time delivery.

- Ensure all operations—from nesting to shipping—work in harmony.

By integrating nesting with scheduling, manufacturers can eliminate inefficiencies, reduce downtime, and deliver high-quality parts that meet customer demands.

How nPower Scheduler™ Bridges the Gap

The nPower Scheduler™ bridges the gap between nesting and scheduling by delivering a comprehensive, automated solution. It not only schedules nested build plates for printing but also accounts for every downstream operation, ensuring your entire additive manufacturing process is optimized for efficiency and profitability.

Final Thoughts

In additive manufacturing, nesting and scheduling are critical components of a seamless production process. Nesting software optimizes the printing phase, while nPower Scheduler™ ensures every subsequent operation is aligned to meet delivery goals. Together, they enable manufacturers to unlock the full potential of their AM operations.

Ready to optimize your additive manufacturing workflow? Discover how nPower Scheduler™ can transform your production process with software-driven precision and automation. Visit npowertech.com today to learn more!