AUTOMATED SCHEDULING

Smart Scheduling for Additive Manufacturing

Take control of your production with nPower Scheduler™—the fully automated, software-driven solution designed for additive manufacturing. Maximize efficiency, reduce waste, and meet delivery deadlines with precision scheduling from build plate to post-processing.

What is Divergent Manufacturing?

A divergent manufacturing process is one where a single work order or job feeds into multiple other jobs in order to produce different end products, each perhaps with differing quantities and delivery dates. In additive manufacturing, a single build plate may be constructed to produce multiple parts. After these parts are printed, there are post-processing steps. Those steps that are common for all parts continue on the same build plate work order. When the post-processing steps differ, the manufacturing process branches into separate routing structures to completion.

What Makes Scheduling Divergent Manufacturing Challenging?

With multiple end products produced from a single build plate, the challenge is to schedule the build plate work order such that all end products are delivered on time, taking into account the different resources and different steps in each of the end product’s post-print processing. In a locked Bill of Material (BOM) environment, where only certain work centers are approved to produce a part, the scheduling becomes increasingly more difficult as capability to produce is an now an additional factor along side resource availability when determining when an operation may start production.

Assign and schedule a work center for simultaneous work on multiple end items

Additive manufacturing requires efficient production scheduling. Different from other scheduling software on the market, the nPower Scheduler™ enables scheduling of multiple end items through a single work center, optimizing production processes and reducing production time, while satisfying customer delivery requirements.

Schedule resources and materials concurrently through the entire shop floor

The nPower Scheduler enables concurrent scheduling across the entire shop floor, optimizing production and reducing waste, while ensuring the delivery of high-quality product on time and on budget.

nPower Scheduler™

Features

- Concurrent scheduling

- Materials (Metal Powders, Polymers, Pellets, etc.)

- Work Centers (Printers, Wire EDM, Milling / Lathe, etc.)

- Labor (Operators, QA/QC, etc.)

- Outside Services (HIP, Painting, Anodizing, etc.)

- Auto selection and schedule of controlled assets based on end item approval matrices

- Scheduling based on calendars of the overall shop and at each individual resource

- Scheduling of operations with similar setups to gain production efficiency

- Accounts for additive printer material availability and viability/quality of material

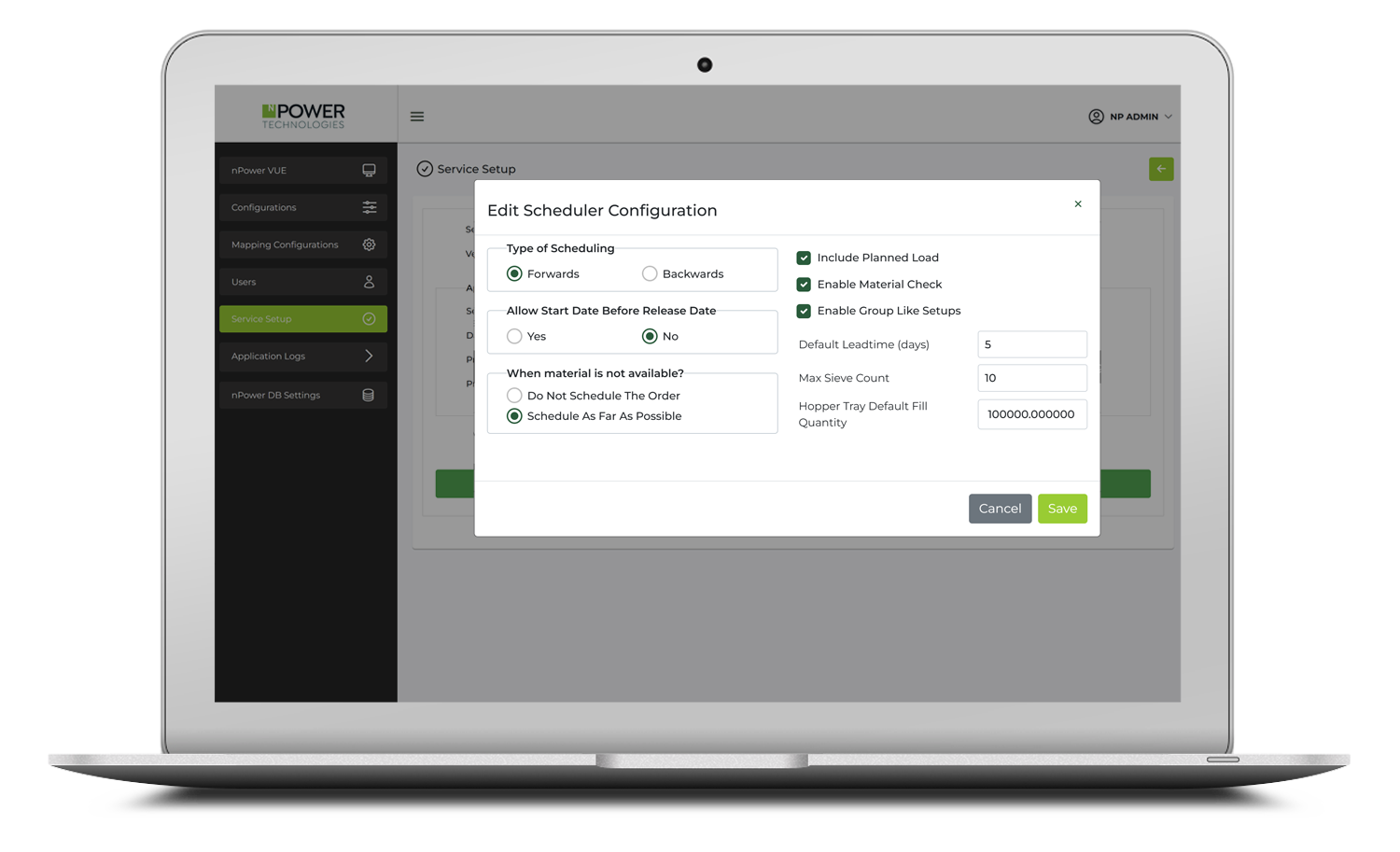

- Runs as scheduled service (i.e., every x hours or daily at x:00 AM) or on-demand

- ERP agnostic

We are Technology Experts for Additive Manufacturers

Proven experience with deep knowledge of manufacturing and scheduling

We help manufacturers across the spectrum of industries, job shops of all sizes, leverage technology to solve their most complex business challenges. We understand the right business software, properly deployed and utilized, can help your company achieve greater levels of performance, increased resource utilization, streamlined operations, improved customer service, and lower costs.