Nesting Software vs. Scheduling Software in Additive Manufacturing: How nPower Scheduler™ Delivers the Only Automated Production Scheduling Software for Additive Manufacturing

In additive manufacturing (AM), nesting software and automated scheduling software play critical roles in optimizing production. While they work in tandem to improve efficiency, they serve distinct purposes at different stages of the manufacturing process. Understanding how they complement each other is essential to being an efficient and profitable additive manufacturer.

What Is Nesting Software in Additive Manufacturing?

Nesting software is designed to optimize the digital arrangement of parts on a 3D printer’s build plate. By automating this process, it ensures the printer’s capabilities are fully utilized, focusing exclusively on the printing phase.

Key capabilities of nesting software include:

- Maximizing Build Plate Capacity: Strategically arrange parts to fit as many as possible without compromising quality.

- Minimizing Print Time: Optimizes layouts for faster, more efficient printing.

- Reducing Material Waste: Places parts in a way that conserves resources.

While nesting software is essential for the 3D printing stage, its scope is limited. It does not address post-print operations, resource allocation, or delivery timelines. This is where nPower Scheduler™, a fully automated, software-driven scheduling solution, takes over to ensure end-to-end efficiency.

What Is Automated Production Scheduling with nPower Scheduler™?

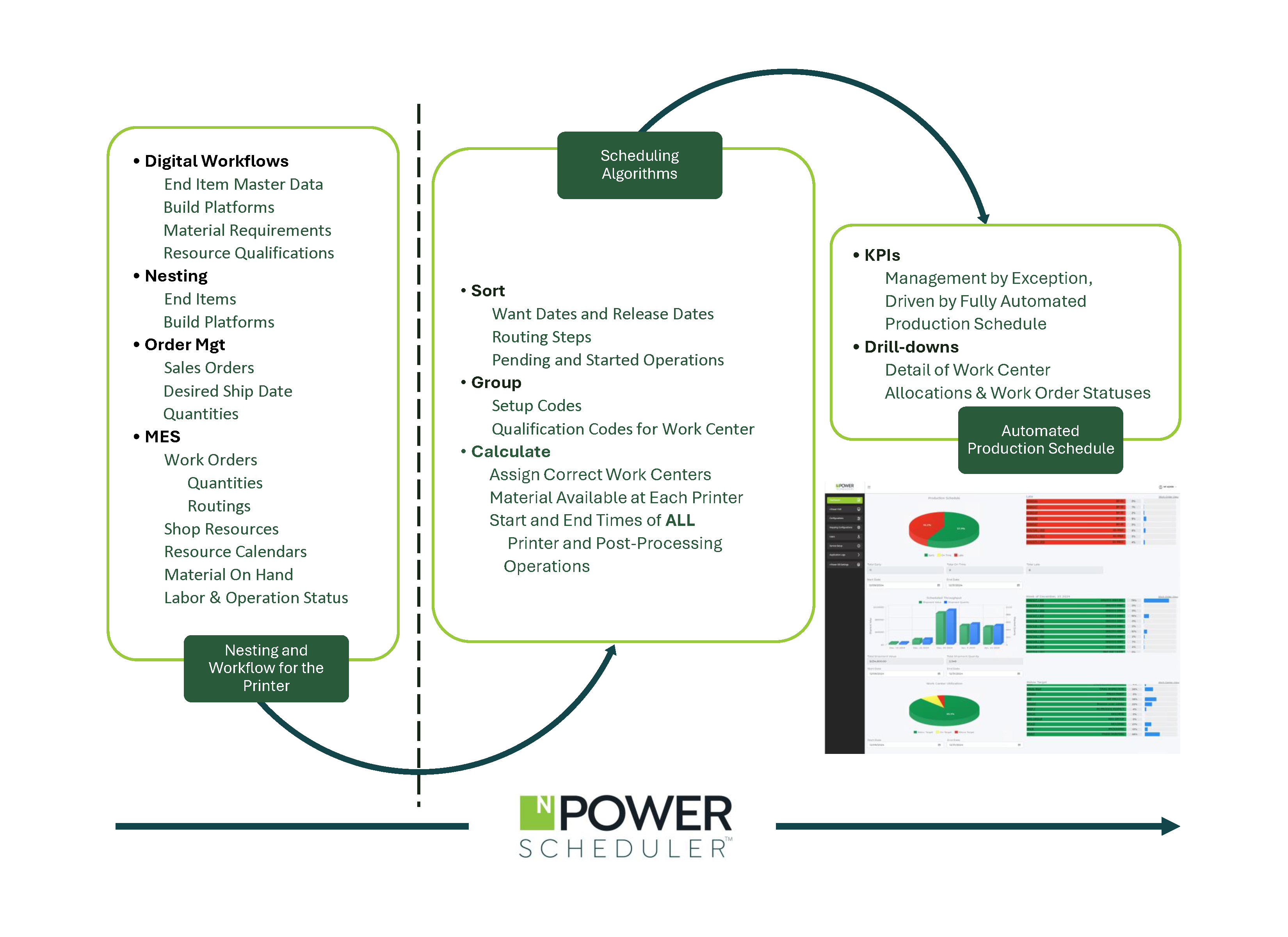

The nPower Scheduler™ is an automated, ERP-agnostic solution tailored to the complexities of additive manufacturing. Unlike manual methods or basic scheduling tools, nPower Scheduler™ provides a comprehensive, software-driven approach that optimizes every stage of production, ensuring precision, efficiency, and on-time delivery.

Key Features of the nPower Scheduler™:

- Automated Precision: Fully software-driven, nPower Scheduler™ eliminates human error, ensuring every task is scheduled accurately.

- Optimized Resource Utilization: Automatically assigns tasks to the right machines, balancing workloads while considering availability, technical requirements, and capacity.

- End-to-End Scheduling: Schedules the entire production process, from 3D printer build plates to post-processing operations like deburring, milling, and inspection—all with a single click.

- On-Time Delivery Assurance: Dynamically adapts to changes, ensuring every job meets customer “want dates” for consistent on-time delivery.

While nesting focuses on optimizing parts on the build plate, nPower Scheduler™ coordinates every step beyond the printer, providing a fully integrated solution for your entire shop floor.

Why Nesting and Scheduling Work Best Together

Additive manufacturing is a complex process involving multiple phases, resources, and deadlines. Nesting ensures the printer is used efficiently, but only scheduling software like nPower Scheduler™ can automate and optimize the full production lifecycle. Together, these tools:

- Maximize efficiency by automating both the printing and post-processing stages.

- Align production goals with business objectives, such as improved resource allocation and on-time delivery.

- Ensure all operations—from nesting to shipping—work in harmony.

By integrating nesting with scheduling, manufacturers can eliminate inefficiencies, reduce downtime, and deliver high-quality parts that meet customer demands.

How nPower Scheduler™ Bridges the Gap

The nPower Scheduler™ bridges the gap between nesting and scheduling by delivering a comprehensive, automated solution. It not only schedules nested build plates for printing but also accounts for every downstream operation, ensuring your entire additive manufacturing process is optimized for efficiency and profitability.

Final Thoughts

In additive manufacturing, nesting and scheduling are critical components of a seamless production process. Nesting software optimizes the printing phase, while nPower Scheduler™ ensures every subsequent operation is aligned to meet delivery goals. Together, they enable manufacturers to unlock the full potential of their AM operations.

Ready to optimize your additive manufacturing workflow? Discover how nPower Scheduler™ can transform your production process with software-driven precision and automation. Visit npowertech.com today to learn more!